T: +86-18953655164

E: 1099778230@qq.com

E: 1099778230@qq.com

Room 1204, Zhongcheng International, Northeast corner of intersection of Wenhua Road and Minsheng East Street, Kuiwen District, Weifang City, Shandong Province

| Availability: | |

|---|---|

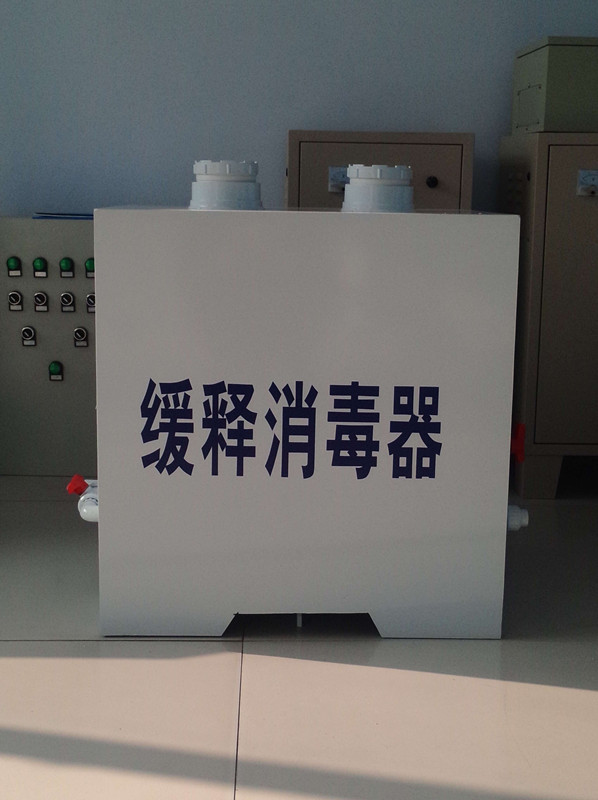

The working principle of a slow-release sterilizer is to achieve slow and continuous release of disinfectants through chemical reactions and physical diffusion processes. Specifically, a slow-release sterilizer usually contains a container for storing liquid disinfectants, which can be hydrogen peroxide, chloride or other highly oxidizing chemicals. Before use, it is necessary to prepare the disinfectant at an appropriate concentration according to the specifications and instructions for use of the equipment, and ensure that its quality meets the relevant standards.

1

Chemical reaction and slow-release mechanism

Chemical reaction: The slow-release sterilizer uses the chemical properties of the disinfectant itself to gradually release the disinfectant through a chemical reaction. This reaction may be spontaneous or triggered by external conditions (such as temperature and humidity changes).

Slow-release mechanism: During the slow-release process, disinfectant molecules slowly seep out of the container into the surrounding environment through diffusion. This slow-release mechanism ensures that the disinfectant is released at a steady rate, thereby maintaining an effective disinfection concentration in the environment.

Environmental adaptability

Although the unpowered slow-release sterilizer itself does not rely on electricity to drive, some advanced models may be equipped with sensors to monitor parameters such as humidity and temperature in the environment. These sensors can help evaluate the disinfection effect and adjust the disinfectant release strategy if necessary. This function may be limited for purely unpowered devices.

Use and Maintenance

Preparation before use: Before using the unpowered slow-release disinfector, you need to ensure that the inside of the device is clean and free of impurities, and the disinfectant is properly installed and placed according to the instructions.

Regular inspection: In order to maintain the normal operation and disinfection effect of the equipment, it is necessary to regularly check the remaining amount and release of the disinfectant, and replenish the disinfectant in time as needed.

Precautions: During use, care should be taken to avoid direct contact of the disinfectant with the skin or eyes to avoid injury. At the same time, good ventilation should be ensured around the equipment to reduce the accumulation of harmful gases.